Getting a Feel for Structure

3-D Printing, Virtual Reality Offer New Ways to Experience Molecules

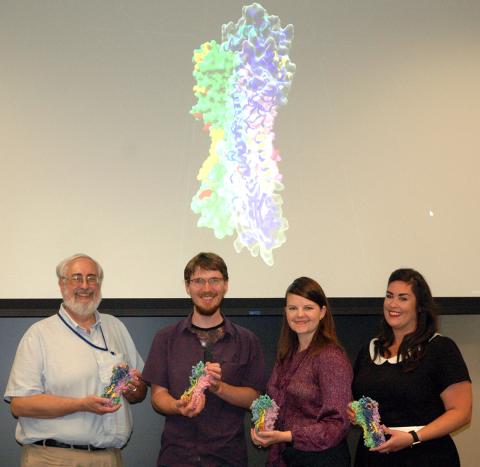

Photo: Chia-Chi Charlie Chang

Scientists have known for some time that influenza is a weed in the lawn of life. Shaped very much like dandelions, new hemagglutinin (HA) proteins that decorate the surface of flu viruses crop up every year—persistent, hardy and unwanted. What’s more, the molecules show an uncanny ability to change annually, outwitting the previous year’s vaccine. That’s why we have to get a new flu shot every year, to fight off the HA molecule’s new look.

Since January, scientists in NIAID’s Vaccine Research Center have used several advanced tech tools to study flu’s structure, to see how it latches onto our body’s cells and figure out the weak spots where a vaccine could best attack and destroy the molecule.

Three-dimensional printing capability places detailed models of flu HA molecules in researchers’ hands. Virtual reality technology lets scientists walk into a molecule and view it from the inside out. These fresh ways of seeing viruses open intriguing new opportunities for research.

Please, Pass the Flu

For several years, VRC deputy director Dr. Barney Graham, a physician and virologist, has kept models of two conformations of the RSV F protein, from respiratory syncytial virus, atop his desk. Graham, in collaboration with Dr. Peter Kwong, a VRC structural biologist, solved the structure of the prefusion form of F and designed the models; NLM printed them in 3-D. Graham refers to them often, reminding other VRC scientists that the models help him figure out spatial relationships for vaccine design.

“I hold these models in my hands almost every day to put new data on antibody binding or protein stability into context of the 3-D structure,” says Graham, chief of the VRC’s Viral Pathogenesis Laboratory.

And his enthusiasm for 3-D printing has infected his whole team.

Imagine the flu molecule is shaped like a flowering weed. As Dr. Michelle Crank, head of the translational sciences core in the Viral Pathogenesis Laboratory, and head of the flu program under Graham, explains, scientists want to cut off the top of the molecule (the part that changes and adapts to evade the immune system every season) and address the constant part—the molecule’s “stem”—that stays much the same from strain to strain.

“The head is the part that the immune system sees best,” Crank says. “To make a universal vaccine—to protect against more than one strain or for more than one year—researchers want to get rid of the head. We hope if we remove it, the immune system will attack the stem.”

That way, a universal vaccine might be developed to attack all strains and save us from getting the yearly shot.

Photo: Carla Garnett

3-D printed models mean the scientists no longer have to imagine molecule shape; they now get a better feel for how the proteins covering the virus move and behave by holding them in their hands.

“When you cut off or change part of a big molecule, what’s left doesn’t just stay in the same shape or fit together the same way on its own,” Crank explains. “Any 3-D model like this might help our eyes find subtle relationships and changes between strains of HA that could give us clues for how to stabilize the stem across all the strains.”

Viruses and their surface molecules are miniscule, far too small to be seen with the naked eye. In fact, most of the molecules scientists study are many thousands of times smaller than a strand of hair. The benefits of a handheld model are obvious.

Sizing, Scaling

“The flu molecule we are working on is absolutely tiny—about 13 nanometers in the longest dimension,” notes James Tyrwhitt-Drake, a scientific visualization specialist in the Bioinformatics and Computational Bioscience Branch of NIAID’s Office of Cyberinfrastructure and Computational Biology. “It’s important to scale the model of the molecule in a deliberate way, so comparisons can be made. The software we use will convert each ångström [0.1 nanometer] in the molecule to a millimeter in the printed object, which is a magnification of precisely 10 million times. However, if the model has delicate features, I will print it larger—15 million or 20 million times—so that they will not break during printing.”

Photo: Carla Garnett

If the molecule is “large” like a whole virus, Tyrwhitt-Drake says, he’ll scale it down to 1 million times, so it will fit in the volume of the printer.

“Not only can you look at it and hold it in your hand,” Crank says, “but if you also have an antibody [model], you can have that antibody come in and bind at a particular binding site or see relationships between the different components.”

First Impressions

All sorts of uses emerged for the 3-D models, which also have become popular props at lectures.

“This molecule is heavier than I expected!” says Dr. Jeffrey Boyington, a structural biologist in VRC director Dr. John Mascola’s Laboratory of Virology and lead designer of the headless HA stem vaccines, recalling his initial reaction to holding the printed HA molecule in his hand. “One of the first things I noticed is that these are great teaching and discussion tools for one-on-one or small group settings. You can easily point to a critical region and others in the room see exactly see what you are referring to in 3 dimensions with the added perspective of seeing the whole molecule.”

New Views Reviewed

When Bill Gates came to call at NIH this past spring, VRC scientists were tapped to give him a demo of some of their latest gadgetry. In addition to literally passing around the flu strains, the cyberinfrastructure team set Gates up with a virtual reality headset and let him take a stroll through an HA molecule.

Noting that the experience was similar to video gaming, Gates wanted to know how an admittedly sophisticated toy could help scientists in the global fight against viruses. Researchers then described the potential impact of their new views.

Photo: Carla Garnett

“When you get inside the goggles,” Crank explains, “you can actually stand in that space and look around at all the side chains coming off of the protein, pointing at you, and you can see how big the space is.

“Not being a structural biologist, I have not spent a lot of time using molecular graphics programs on a computer, so seeing inside the molecule and looking out was a totally new perspective for me,” she adds. “Appreciating the gaps inside a 3-D structure like the HA molecule is something you cannot do from the printed models, since you cannot see ‘through’ to the inside. And sometimes it’s understanding that inner structure that can reveal helpful relationships for designing ways to stabilize vaccine immunogens that utilize only part of the whole molecule, but still need to present an authentic or accurate shape to the immune system.”

Of course, no matter how advanced, technology alone won’t produce effective vaccines overnight, scientists acknowledge. Having more up-close and personal interactions with viruses, however, will help researchers better understand what we’re up against.

“We will still be using desktop molecular graphics programs for most of our work,” concludes Boyington, “but as we periodically examine the 3-D print models or walk through VR in the coming months, we might have some eureka moments of insight since these views give us a slightly different perspective than we are used to.”